Masonry Anchors and Ties and the 2016 TMS402 Building Code

The 2016 version of the Masonry Building Code has been accepted as a part of the 2018 International Building Code. Earlier code modifications have taken place in 2013, 2011, 2008 and 2005 and the next version will not be out until 2022. Below are the current code requirements for masonry anchors. Please be aware that these are the “minimum” requirements for code compliance.

Key Features of the TMS402/602-16 Building Code

- Backup walls must be designed to resist water penetration. Water entering the interior is one of the main causes of brick veneer failures. Water will get in the cavity so the proper design of keeping the water from entering the building by waterproofing the backup and getting it out of the air cavity is vital.

- Flashing and weep holes must be designed to eliminate the water in the cavity. The code specifies minimum 3/16” i.d. weep tubes spaced less than 33 inches on center. (While this does drain water, it does not ventilate the cavity. In order to get good airflow to dry out the cavity, Heckmann’s recommends using a vent-type weep system that is the full height of the brick manufactured from a polyester mesh or a cell-type polypropylene material and spaced no more than 24” apart. Vents should also be installed at the very top course of the wall to allow airflow through the entire cavity for drainage and drying.)

As in previous versions, there are 5 types of Veneer Anchors

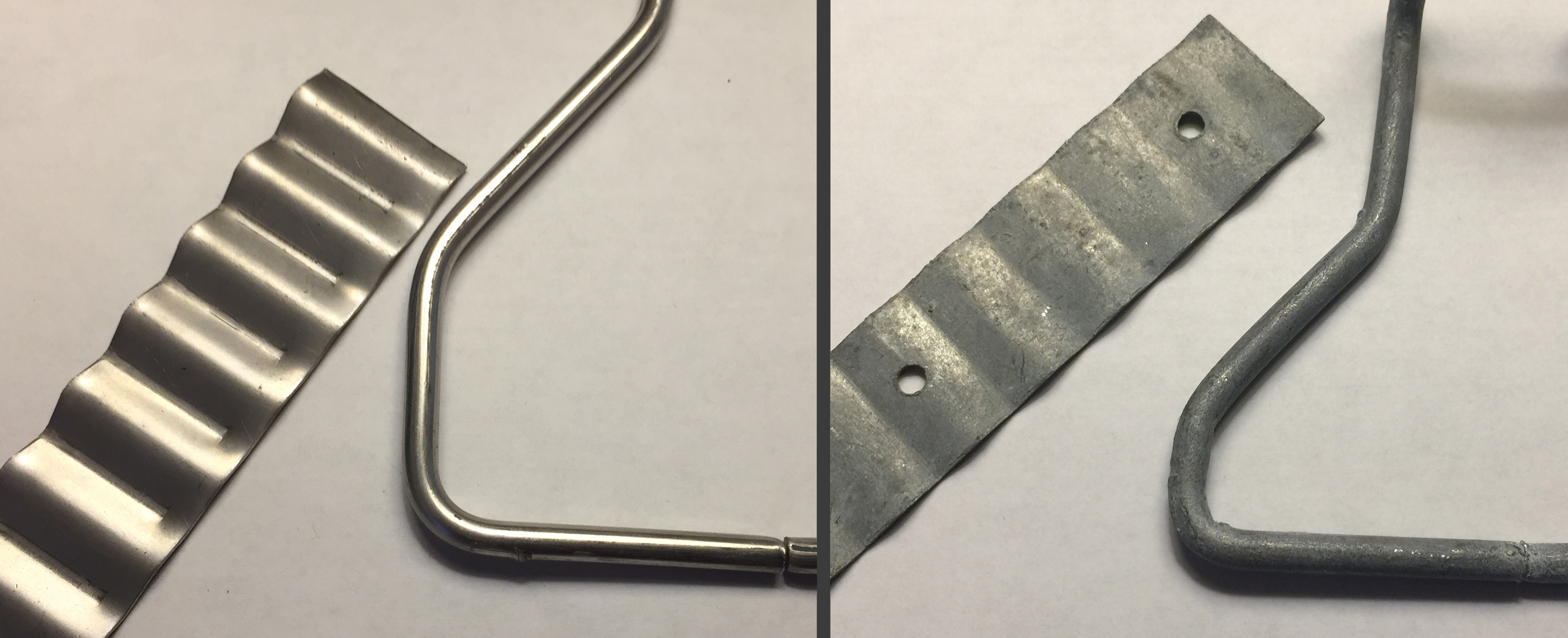

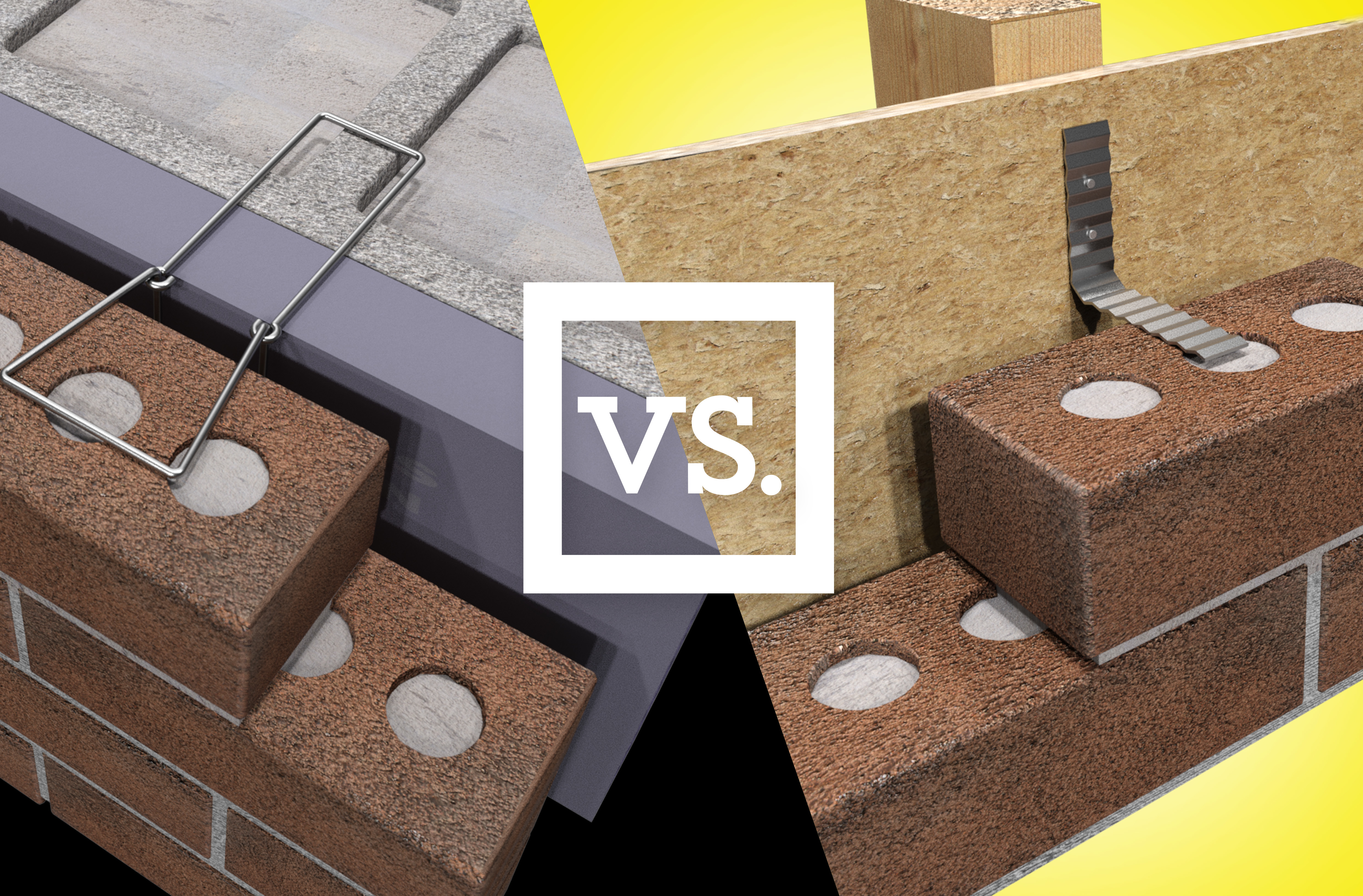

1. Corrugated Sheet-Metal Anchors: Minimum 22 gage x 7/8” wide with corrugation wavelengths of 0.3” to 0.5” and an amplitude of 0.06” to 0.10”. These anchors can only be used with a maximum 1” airspace and can only be used with wood stud backups.

2. Sheet-Metal Anchors: Minimum 16 gage x 7/8” (Heckmann’s standard Sheet Metal Anchors are 1-1/4” wide for greater strength). The Sheet-Metal Anchors are bent in the factory. These too can only be used with wood stud backups. The sheet-metal anchors are typically used with airspaces over 1”.

3. Wire Anchors: Minimum of 9 gage wire with ends bent in the veneer a minimum of 2” long. (Heckmann’s minimum wire anchor diameter is 3/16”). The wire anchors can be used with Wood and CMU backups.

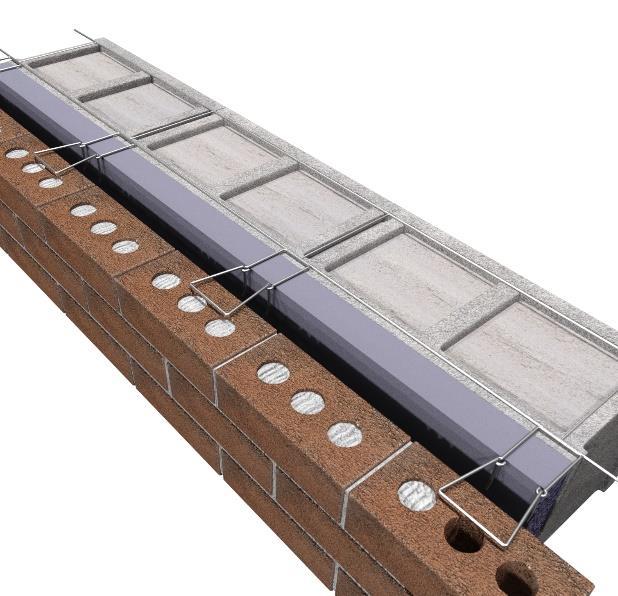

4. Joint Reinforcement: Ladder or Pintle-Eye type is allowed. A minimum 9 gage wire diameter with welded cross wires 16” on center is required. For cavities over 4-5/8” the reinforcement wire diameter must be 3/16”. Joint reinforcement is for CMU backups only.

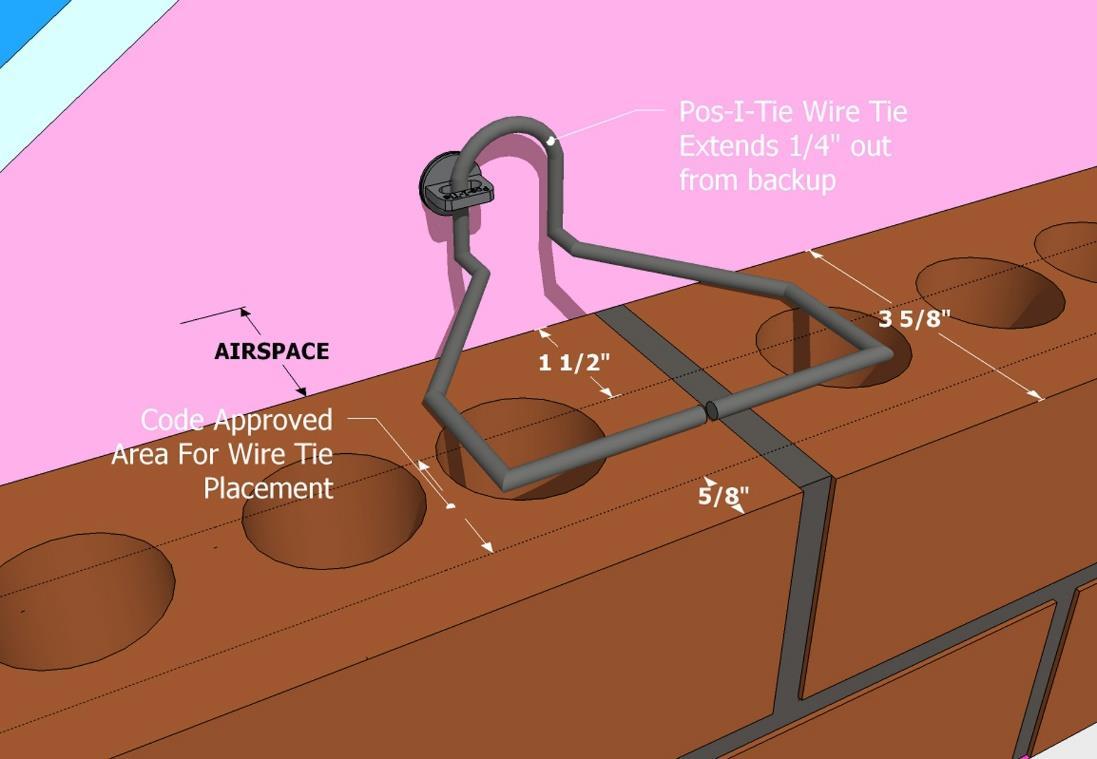

5. Adjustable Anchors: These are 2-piece anchors with one piece attached to the backup and the other to the veneer. The maximum clearance between the two connecting parts is 1/16”. For Pintle Anchors, a minimum wire diameter of 3/16” is required and the offset between the pintle and the anchor cannot exceed 1-1/4”. The anchor attached to the backup can be a barrel anchor with a minimum outside diameter of 1/4" (Heckmann’s Pos-I-Tie® is 3/8” diameter) or a plate-type anchor that is a minimum of 14 gage x 1-1/4” wide. Adjustable anchors allow for vertical deflection and can be used with all backups. (Steel Stud, Wood Stud, CMU, Concrete, Structural Steel.)

- Anchor Spacing: Adjustable Anchors and Corrugated Sheet-Metal Anchors require one anchor every 2.67 ft² (16” x 24”). All other anchors require one anchor every 3.5 ft² (16” x 32”) Additional anchors are required within 12” around openings larger than 16” in either dimension. (Heckmann recommends 16” x 16” or 16” x 24” as the maximum distances for veneers)

- Joint Thickness and Anchor Placement in Veneers: The mortar joint should be twice the thickness of the embedded anchor. (3/16” max for a 3/8” joint) Anchors in the veneer must be embedded in the mortar joint a minimum of 1-1/2” in from the airspace and no closer than 5/8” from the veneer exterior.

- New Provisions for Wider Cavities: Previous versions of the TMS402 code required engineering for cavities over 4-1/2”. The 2016 code version allows for the use of prescriptive anchors for cavities over 4-1/2” up to 6-5/8” as long as the airspace is 2” or under. Wire anchors and joint reinforcement must be 3/16” diameter.

- Airspace: The minimum airspace is 1”. The tolerance allowed in the specifications section is -1/4” to +3/8”. (Heckmann’s recommends a 2” airspace which allows for better water drainage and easier installation for the bricklayers.)

Attachment to Backup Walls:

1. Wood Backup: Use a corrosion-resistant 8d common nail or fastener with equivalent or greater pullout strength. Corrugated Sheet-Metal Anchors, Sheet Metal Anchors, Wire Anchors and Adjustable Anchors are permitted with wood-backups. For corrugated sheet-metal anchors the fastener must be within 1/2" of the 90° bend in the anchor. (Heckmann recommends using 8d Ring-Shank nails or #10 screws with a minimum shank diameter of 3/16” for all wood backups as this is the requirement for Seismic zones D and above)

2. Steel Studs: Use Adjustable Anchors only. Attach to steel studs with a minimum #10 corrosion-resistant screw 3/16” diameter minimum. Minimum thickness of steel studs with exterior brick veneers is 18 gage. (Heckmann recommends a minimum of 16 gage steel studs)

3. Concrete Backup: Use Adjustable Anchors only. There are no code requirements as to the attachment of anchors to concrete. (Heckmann recommends using Tapcon® style screws minimum 3/16” diameter x 1-3/4” long or equivalent expansion anchor)

4. CMU/Masonry Backup: Use Wire Anchors, Adjustable Anchors or Joint Reinforcement. For non-joint reinforcement anchors Heckmann recommends the same fasteners as the Concrete Backup attachments.

Every TMS402 code cycle and IBC code cycle have changed over previous versions. It is important to be aware of the IBC code in place in the jurisdiction of your project. There are municipalities across the US that are still using 2009, 2012 and 2013 versions of the International Building Code. If your project is in a city that uses an earlier version, you need to comply with that version.