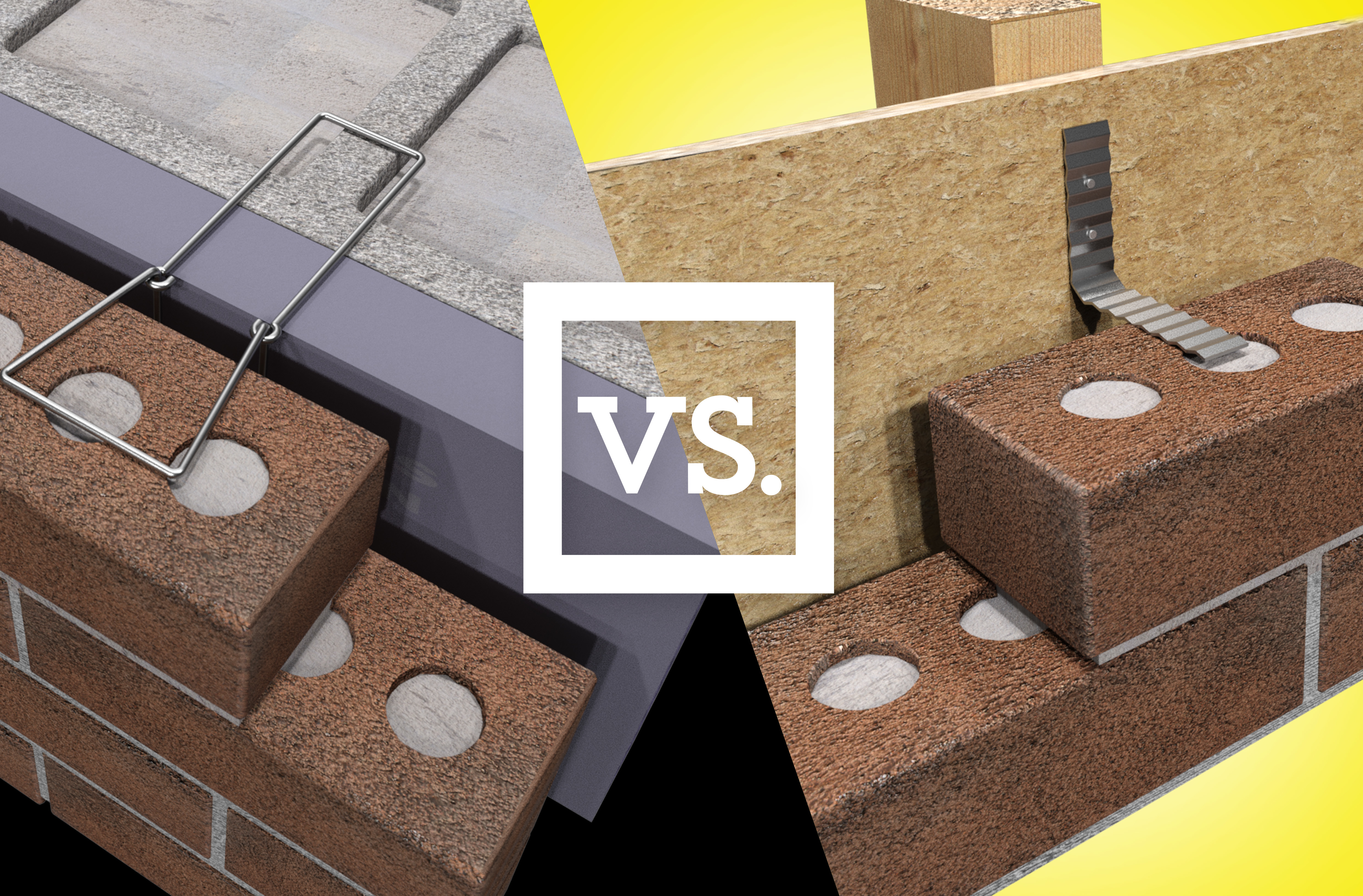

Which are the best masonry anchors? Hot-Dip Galvanized vs Stainless Steel

In the United States, The TMS 402 building code allows for the use of Hot-Dip Galvanized Steel and Type 300 Stainless Steel for anchors in exterior walls. How does one decide which material they should employ in their construction project? Both are high-quality materials and provide an impressive amount of corrosion resistance, but each has its own vulnerabilities and strengths and both should be considered when specifying building materials.

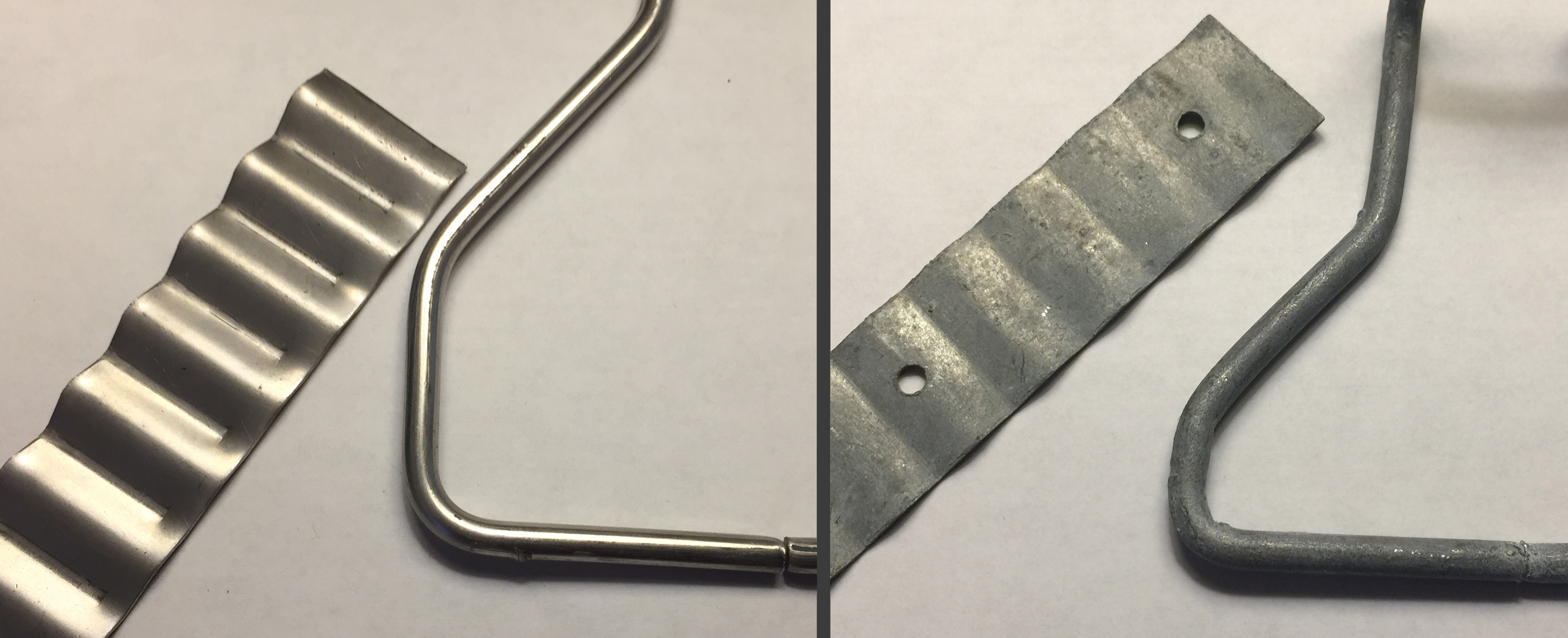

The first difference between the two materials is the way that they are manufactured. Stainless is an alloy steel, which means that it contains between 16 to 24 percent chromium, up to 35 percent nickel, and small amounts of carbon and manganese. To create stainless steel, ordinary steel, chromium, and the other elements are blended in their molten state. To create galvanized steel, ordinary steel is coated by dipping the products in melted molten zinc, hence the name “hot-dipped.”

Galvanization, the practice of applying protective zinc for industrial use, is commonly used with both steel and iron. Zinc can be problematic when found in excess amounts in our environments, and when found in bodies of water can wreak havoc on flora, animals, and humans. As building products made of galvanized steel break down over time (as all products naturally do), the environment’s exposure to zinc increases.

Secondly, the two materials offer different resistance against the elements. Galvanized steel can withstand water exposure, but not saltwater exposure and should not be used in buildings near saltwater. Galvanized steel is a coating over plain steel. If that coating is compromised, the steel underneath will rust. Stainless steel is resistant to corrosion due to the added chromium. Stainless steel can withstand water. There are just a few instances where Type 304 stainless steel is not completely resistant against its surroundings. Chlorine and salt exposure will actually cause Type 304 stainless to degrade, so this is not the best metal to use near pools, wastewater treatment plants or the ocean. Type 316 Stainless Steel has an added molybdenum element that resists salt and chlorides. Also, stainless steel is not resistant to itself. Galling can occur when friction transpires between two pieces of stainless steel. Galling is a form of wear that can stick or friction-weld two pieces together.

Strength and longevity are other differing factors in galvanized and stainless steel. As we previously mentioned, stainless steel is an alloy while galvanized steel is a zinc coating applied over Plain steel. This zinc coating wears down over time, so all that’s left is ordinary steel, which is not corrosion-resistant. Because stainless steel is blended with chromium which cannot independently wear down and become less effective. Stainless steel lasts much longer than galvanized steel, so when the longevity of the building project is of importance, using stainless steel is recommended.

Stainless steel is much stronger than plain steel hotdip galvanized. Stainless steel has a tensile strength between 75-90 ksi and a yield strength between 30-40 ksi where Hotdip steel has a tensile strength of 38-50 ksi and a yield strength between 21-31 ksi.

The Type 300 stainless steel family is the code required stainless for commercial building projects, but when the project does not require the longevity and strength of stainless steel, hotdip galvanized steel is a perfectly good choice. As hotdip galvanized steel costs less than stainless steel, you can cut project costs by going that route if the project allows for it. - Both stainless and hotdip will provide the necessary requirements to comply with the current building codes.