Determining the correct Pos-I-Tie® Barrel Type and Length for your project.

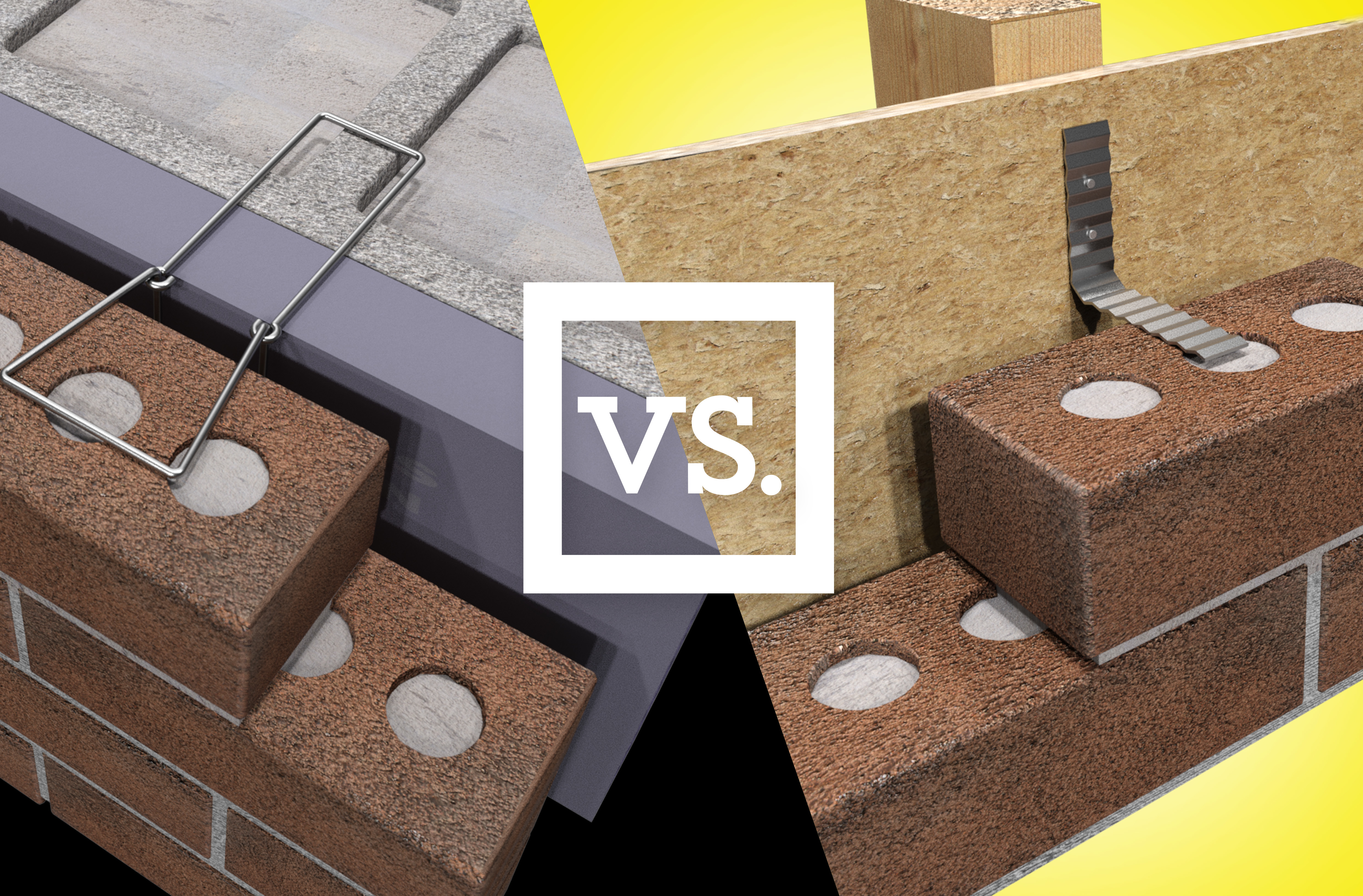

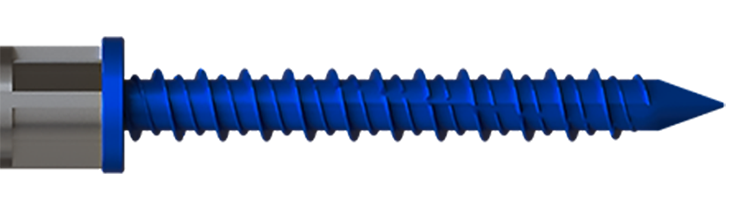

The Pos-I-Tie® was invented in 1985 and was the first barrel type veneer anchor in the marketplace. This system allows the transfer of lateral loads between the brick veneer and the backup directly through full sheets of sheathing without imparting any forces onto the sheathing. Not all sheathing is the same. It is important to analyze the wall configuration to determine the type and size of your masonry anchor to insure the correct Pos-I-Tie® is used for your project.

1. DETERMINE THE BACKUP WALL FOR THE SCREW TYPE

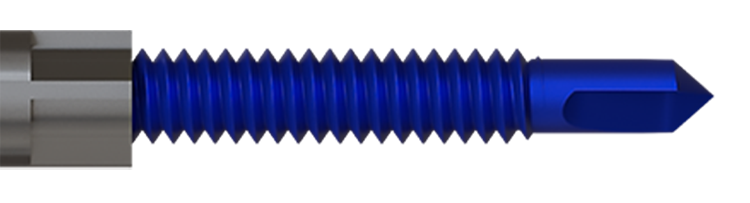

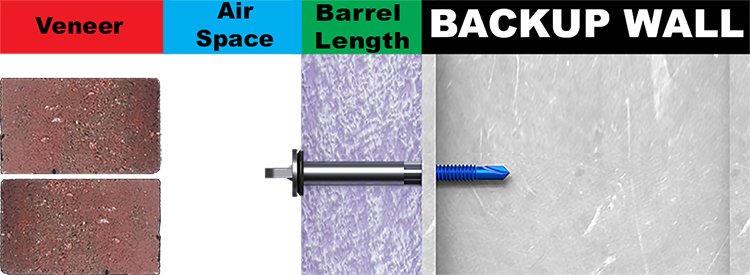

A. Steel Stud Backup Wall: Self-Drilling Screws (Standard catalog numbers start with 75SD(xxxx)

This type of screw will drill and tap the steel stud without the need to pre-drill a hole. Use with 18 gauge – 12 gauge studs.

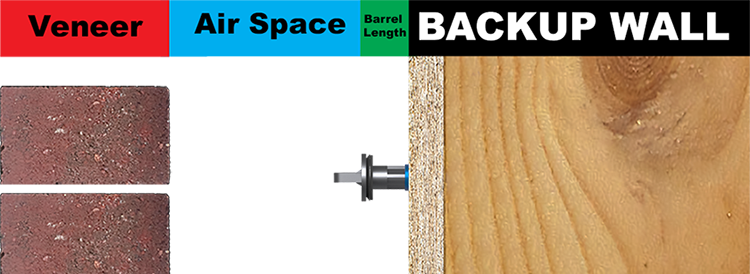

B. CMU/Concrete/Wood/Precast/ICF: (Standard catalog numbers start with 75TC(xxxx)

CMU, Concrete, Precast and ICF require pre-drilling a 3/16” dia hole 2” deep into the backup.

Wood Stud backups do not require pre-drilling.

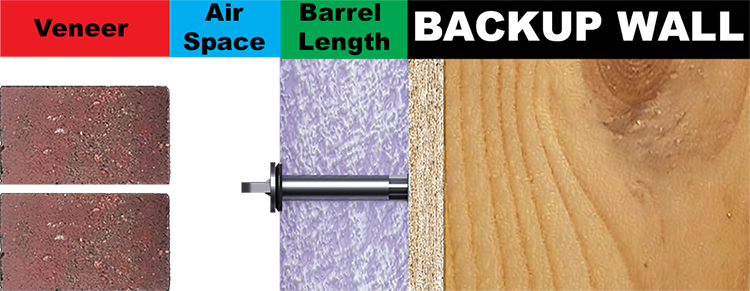

2. ANALYZE THE BUILDING ENVELOPE WALL

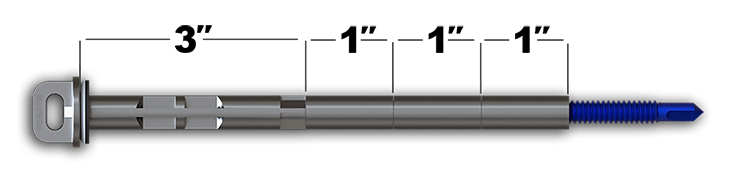

The base of the Pos-I-Tie® Barrel (where the screw is attached) is configured to bore through insulation and gypsum boards. The barrel length is determined by the combined dimensions of these elements. The barrel portion will NOT go through OSB, Plywood or steel faced sheathing. Below are several of the common wall configurations.

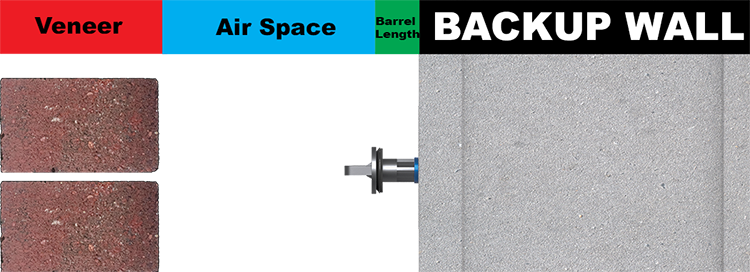

A: Brick Veneer - Air Space - No Sheathing - Backup

(This configuration would not be used with steel or wood studs.)

The smallest barrel length is 5/8" with an overall length of 1-1/4”. For this configuration, the Pos-I-Tie® requires a minimum

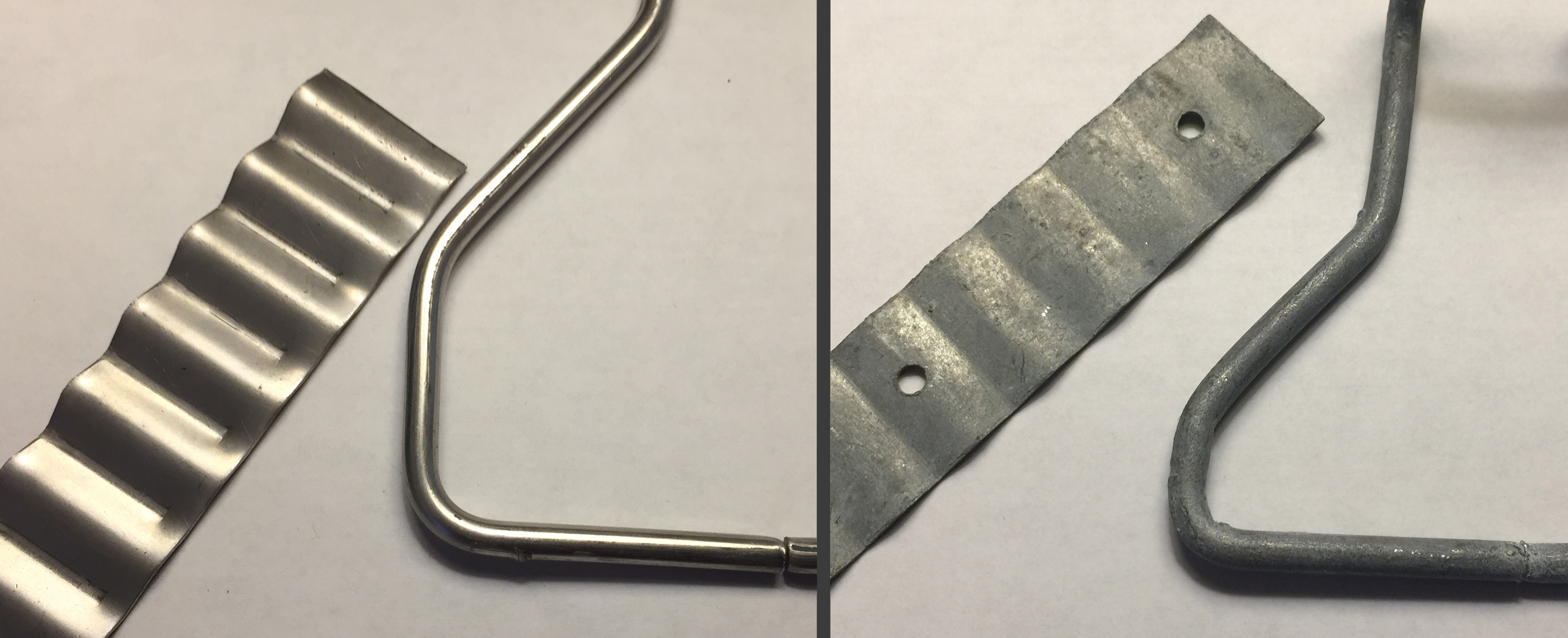

1-1/4” cavity between the brick and the backup. If you have this configuration with an airspace under 1-1/4" consider using Heckmann 315-D Screw-On Plates with #316 Triangle Ties.

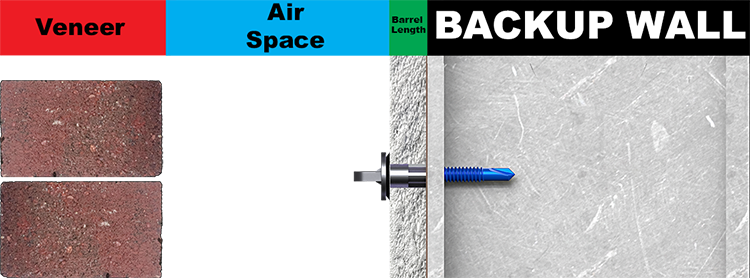

B. Brick Veneer - Air Space - Gypsum Board (no insulation)- Backup

The 5/8” barrel screw is used with 1/2” and 5/8” gypsum boards. With both sizes, the EPDM washer will seal the hole.

Some specifiers are using double layers of gypsum against the backup for

additional R values. Make sure you check for this. If this is the case,

the Pos-I-Tie® Barrel length will be the combined thickness of the

gypsum boards. Please see “Special Conditions” at the end of this

article. The extra-long self-drilling screw is required for double

gypsum board projects.

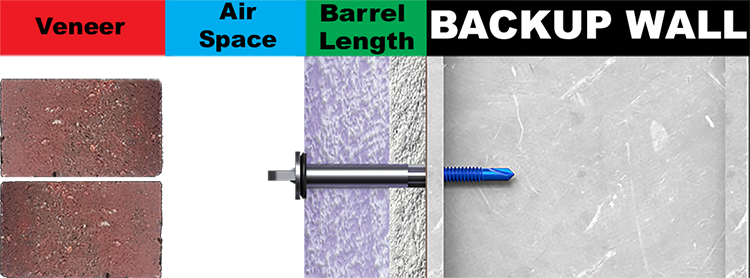

C. Brick Veneer- Air Space - Insulation - Gypsum Board - Backup

The Pos-I-Tie® barrel length will be the combination of the Gypsum board thickness and the insulation thickness.

(This is a common wall configuration for steel and wood studs)

D. Brick Veneer - Air Space - Insulation only - Backup

The Pos-I-Tie® barrel length will be the thickness of the insulation. (Insulation can be rigid, spray-on or mineral wool)

(This is a common wall configuration for CMU walls and some steel stud walls)

E. Brick Veneer - Air Space -Plywood - Backup

The Pos-I-Tie® Barrel will not go through Plywood or OSB. Only the screw will go through and into the backup. The smallest barrel length is 5/8" with an overall length of 1-1/4”. For this configuration, the Pos-I-Tie® requires a minimum 1-1/4” airspace. If you have this configuration with an airspace under 1-1/4" consider using Heckmann 315-D Screw-On Plates with #316 Triangle Ties.

F. Brick Veneer - Air Space - Insulation - Plywood/OSB - Backup

The Pos-I-Tie® Barrel will not go through Plywood or OSB. Only the screw will go through and into the backup. The Pos-I-Tie® barrel length will be the thickness of the insulation. (Note: If your situation has steel stud backup with plywood see “Special Conditions” at the end of this article. The extra-long self-drilling screw will be needed to penetrate through the plywood and into the steel stud.

Special insulation panels: There are several new insulation panels on the market that have wood or steel on the outside of the insulation panel at the airspace. Zip System®, Hunter Xci AEGIS, etc. Contact Heckmann’s for details on masonry anchor options for these types of systems.

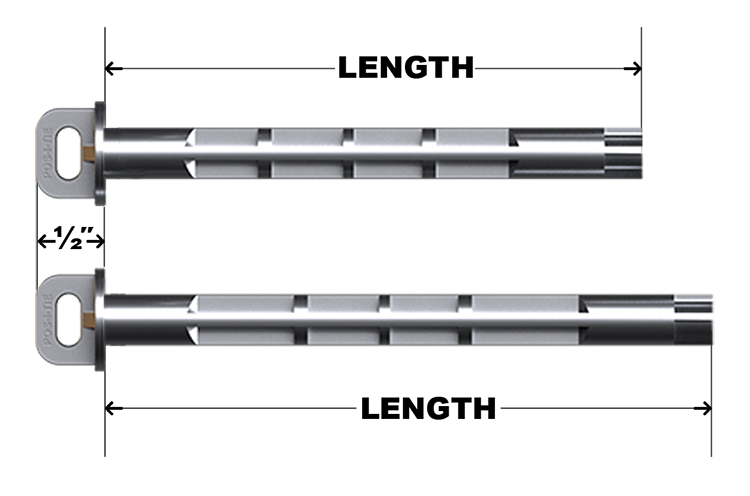

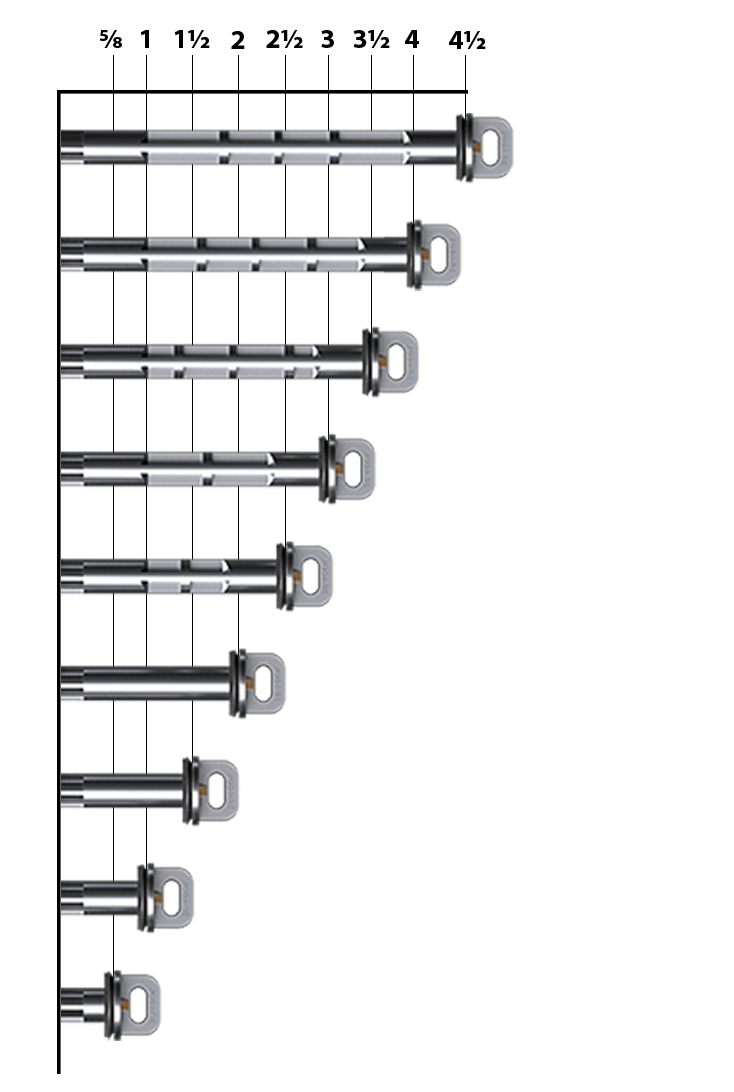

3. POS-I-TIE® BARREL LENGTHS

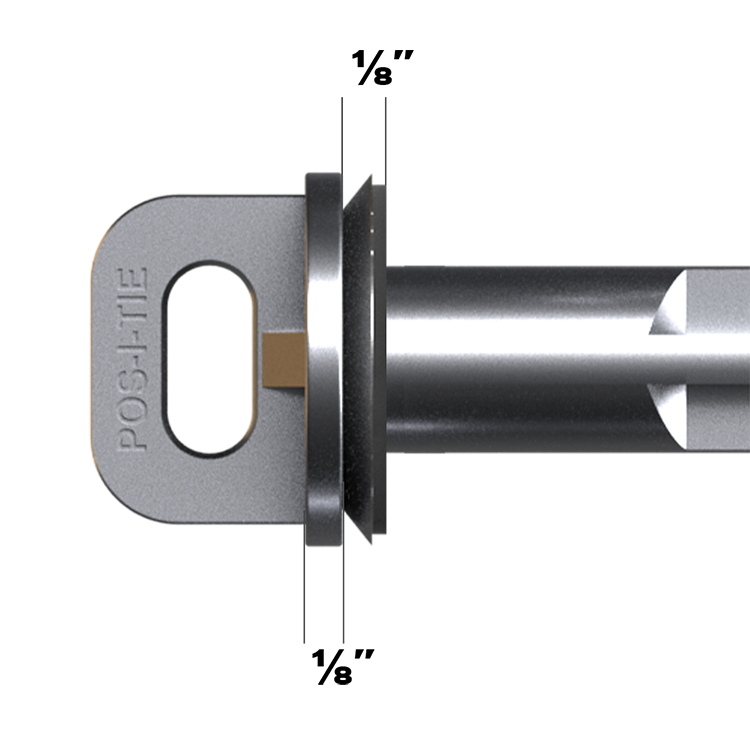

The listed lengths of the Pos-I-Tie® barrels are the lengths matching the combined sheathing thickness. The Pos-I-Tie® has a 1/8” tolerance above and below the listed length. The head of the barrel will protrude 1/2” into the airspace from the insulation.

The steel-backed EPDM washer is 1/8” thick and will either dimple into the insulation or rest right on the insulation – both cases seal the hole drilled through the insulation. The Pos-I-Tie® system holds the insulation tightly against the backup wall preventing any water or air from entering between the gypsum and the insulation. There is no need to have a 2nd seal at a barrier that is between the gypsum and the insulation. This system has been in use for 35 years with no water failures at the anchor locations.

1/8” tolerance with EPDM washer under the flanged head.

Standard Barrel Lengths are 5/8”, 1”, 1.5”, 2”, 2.5”, 3”, 3.5”, 4” and 4.5”

Longer custom lengths are available in ½” increments with our factory-assembled spacers attached to our standard barrels:

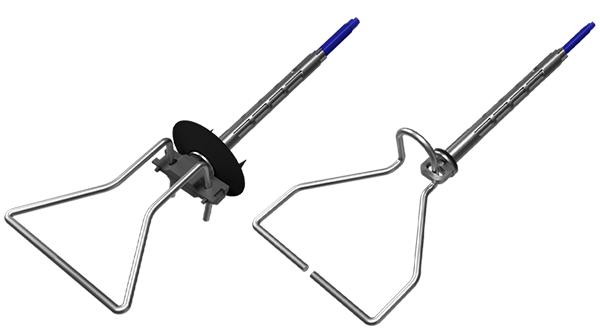

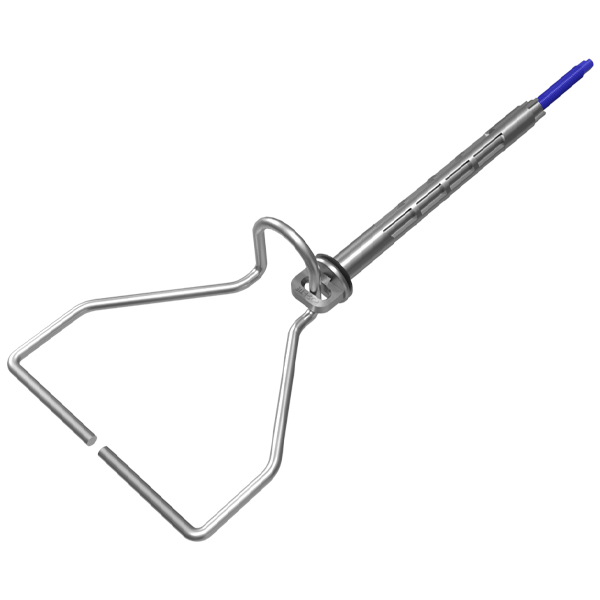

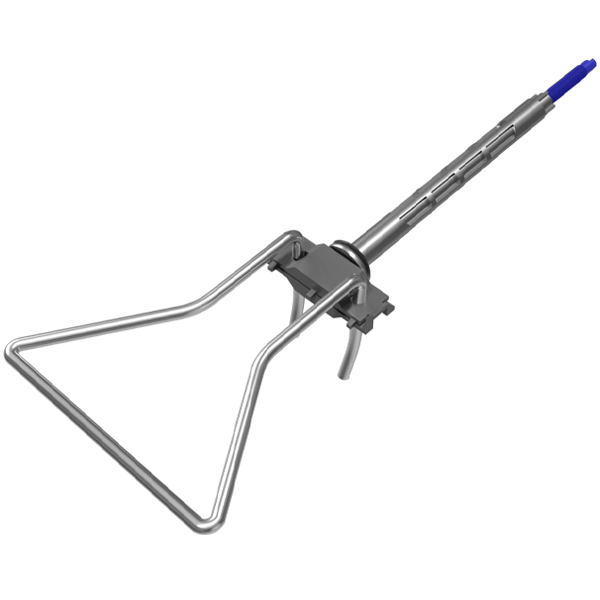

4. WIRE TIES

There are two different wire ties: one for the Original Pos-I-Tie® System and one for the ThermalClip® Pos-I-Tie® System. Both ties are 3/16” diameter in either Hotdip Galvanized After Fabrication or Type 304 Stainless Steel. The standard lengths are 3”, 3-1/2”, 4” and 5”. Custom lengths are available.

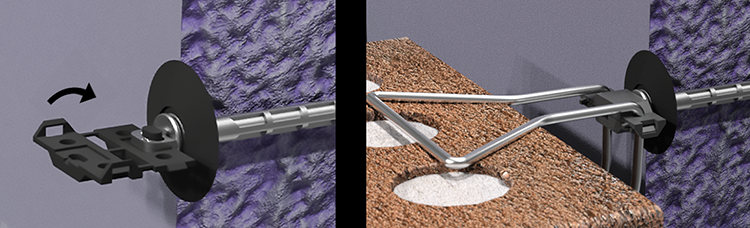

The Original Pos-I-Tie® System utilizes a Triangle Type Wire Tie that is threaded through the barrel screw

The ThermalClip® Pos-I-Tie® System utilizes a pintle wire tie that can be inserted into the ThermalClip®.

The wire ties are not interchangeable. You cannot use a pintle tie with the Original Pos-I-Tie® and you cannot use the looped Triangle tie with the ThermalClip® Pos-I-Tie®,

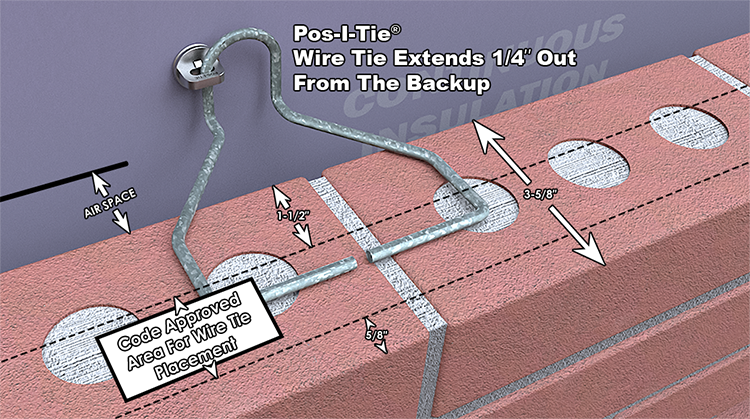

------------

The TMS 402 Building Code requires the wire ties to be at least 1-1/2” into the brick from the airspace, but no closer than 5/8” from the exterior wall. That allows for a 1-1/2” area for the correct placement of the wire tie.

The minimum length formula for the wire tie is: Airspace - .25 + 1.5

The maximum length formula for the wire tie is: Airspace - .25 + 3

AIRSPACE |

MINIMUM TIE LENGTH |

MAXIMUM TIE LENGTH |

STANDARD TIES THAT FIT |

RECOMMENDED TIE LENGTH |

1” |

2-1/4” |

3-3/4” |

3”, 3-1/2” |

3” |

1-1/2” |

2-3/4” |

4-1/4” |

3”, 3-1/2”, 4” |

3-1/2” |

2” |

3-1/4” |

4-3/4” |

3-1/2”, 4” |

4” |

2-1/2” |

3-3/4” |

5-1/4” |

4”, 5” |

5” |

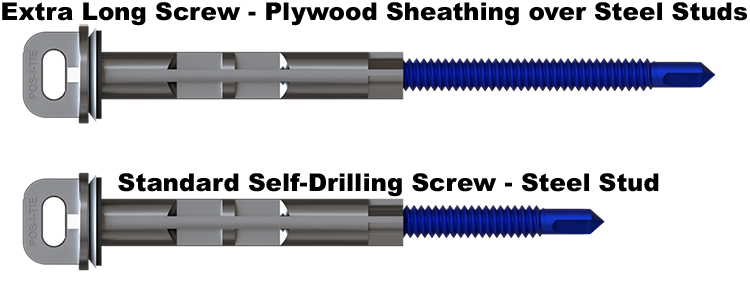

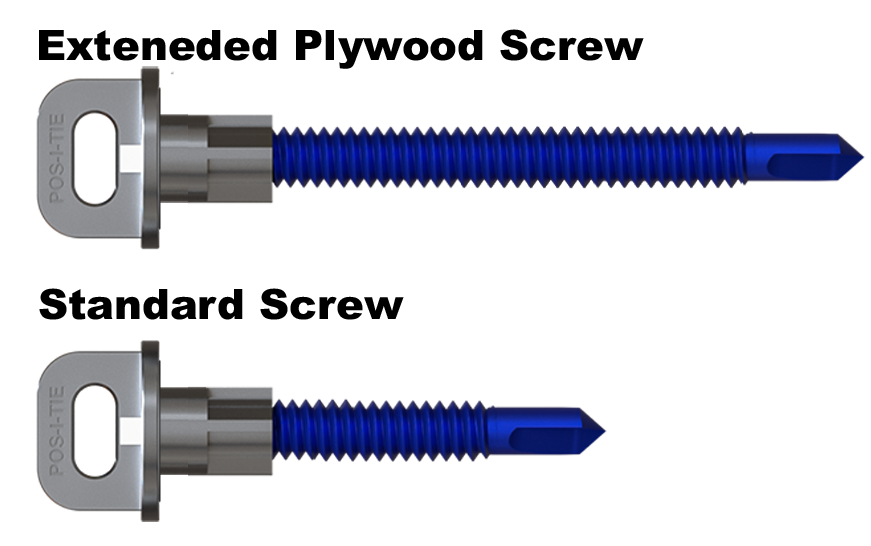

5. SPECIAL CONDITIONS

The Heckmann Pos-I-Tie® System has additional add-ons for unique situations with the self-drilling screws for steel studs.

A: Extra Long Screw

Used for steel studs with Plywood/OSB sheathing or double gypsum boards.

C. ThermalGrip® CI (Continuous Insulation) washer.

The Pos-I-Tie® barrel screws can also act as CI fasteners which eliminate separate backup penetrations for CI fasteners and masonry fasteners.

There are 3 types of CI washers available:

75PW 2" plastic washer

75SW Steel faced 1-1/2" diameter washer

75TG Prong-Type 2" plastic washer

D. The Pos-I-Tie® ThermalClip®.

The ThermalClip® snaps onto the loop in the airspace creating a break in the thermal transfer between the wire tie and the barrel screw. You must use the 282-N Series Pintle Wire Ties with the ThermalClip®. The Pos-I-Tie® Triangle wire ties will not work with the ThermalClip®.

Standard Catalog Numbers for the Pos-I-Tie® Veneer Anchoring System

Standard Catalog Number |

Description |

POS-I-TIE® SELF-DRILLING STEEL STUD BARREL SCREWS |

|

75SDSN |

5/8" Barrel Self-Drilling Steel Stud Screw with EPDM washer |

75SDMN |

1" Barrel Self-Drilling Steel Stud Screw with EPDM washer |

75SDMNA |

1-1/2" Barrel Self-Drilling Steel Stud Screw w/EPDM washer |

75SDLN |

2" Barrel Self-Drilling Steel Stud Screw with EPDM washer |

75SDLNA |

2-1/2" Barrel Self-Drilling Steel Stud Screw w/EPDM washer |

75SDLLN |

3" Barrel Self-Drilling Steel Stud Screw w/EPDM washer |

75SDLLNA |

3-1/2" Barrel Self-Drilling Steel Stud Screw w EPDM washer |

75SDLLM |

4" Barrel Self-Drilling Steel Stud Screw with EPDM washer |

75SDLLMA |

4-1/2" Barrel Self-Drilling Steel Stud Screw w/EPDM Washer |

POS-I-TIE® CMU/CONCRETE/WOOD BARREL SCREWS |

|

75TCSN |

5/8 inch Barrel CMU/Concrete Screw with EPDM washer |

75TCMN |

1 inch Barrel CMU/Concrete Screw with EPDM washer |

75TCMNA |

1-1/2 inch Barrel CMU/Concrete Screw with EPDM washer |

75TCLN |

2 inch Barrel CMU/Concrete Screw with EPDM washer |

75TCLNA |

2-1/2 inch Barrel CMU/Concrete Screw with EPDM washer |

75TCLLA |

3 inch Barrel CMU/Concrete Screw with EPDM washer |

75TCLLLN |

3-1/2 inch Barrel CMU/Concrete Screw with EPDM washer |

75TCLLMN |

4 inch Barrel CMU/Concrete Screw with EPDM washer |

75TCLLPN |

4-1/2 inch Barrel CMU/Concrete Screw with EPDM washer |

POS-I-TIE® TRIANGLE WIRE TIES |

|

75T3H |

3/16 x 3 inch Hotdip Galvanized Triangle Wire Tie |

75T3S |

3/16 x 3 inch Stainless Steel Triangle Wire Tie |

75T35H |

3/16 x 3-1/2 inch Hotdip Galvanized Triangle Wire Tie |

75T35S |

3/16 x 3-1/2 inch Stainless Steel Triangle Wire Tie |

75T4H |

3/16 x 4 inch Hotdip Galvanized Triangle Wire Tie |

75T4S |

3/16 x 4 inch Stainless Steel Triangle Wire Tie |

75T5H |

3/16 x 5 inch Hotdip Galvanized Triangle Wire Tie |

75T5S |

3/16 x 5 inch Stainless Steel Triangle Wire Tie |

POS-I-TIE® THERMALCLIP® AND PINTLE WIRE TIES |

|

75TC |

Pos-I-Tie® ThermalClip® |

282N3H |

Pintle Tie 3/16 x 3 Hotdip Galv |

282N3S |

Pintle Tie 3/16 x 3 Stainless Steel |

282N35H |

Pintle Tie 3/16 x 3-1/2 Hotdip Galv |

282N35S |

Pintle Tie 3/16 x 3-1/2 Stainless Steel |

282N4H |

Pintle Tie 3/16 x 4 Hotdip Galv |

282N4S |

Pintle Tie 3/16 x 4 Stainless Steel |

282N5H |

Pintle Tie 3/16 x 5 Hotdip Galv |

282N5S |

Pintle Tie 3/16 x 5 Stainless Steel |

POS-I-TIE® 610-S 2" DIAMETER WASHER FOR CONTINUOUS INSULATION |

|

610-S |

Thermal-Grip™ Standard 2" diameter plastic washer |

Updated December 2020