Anchor brick veneer to backups using the Pos-I-Tie® Barrel-Screw Anchoring System

The Pos-I-Tie® is a 2-piece adjustable veneer anchor. The Pos-I-Tie system has been the premier anchor of choice for mason contractor’s all over the country. Pos-I-Tie was the first barrel-screw masonry anchor back in 1985 and is still the first choice of architects and contractors. It is available in three different styles.

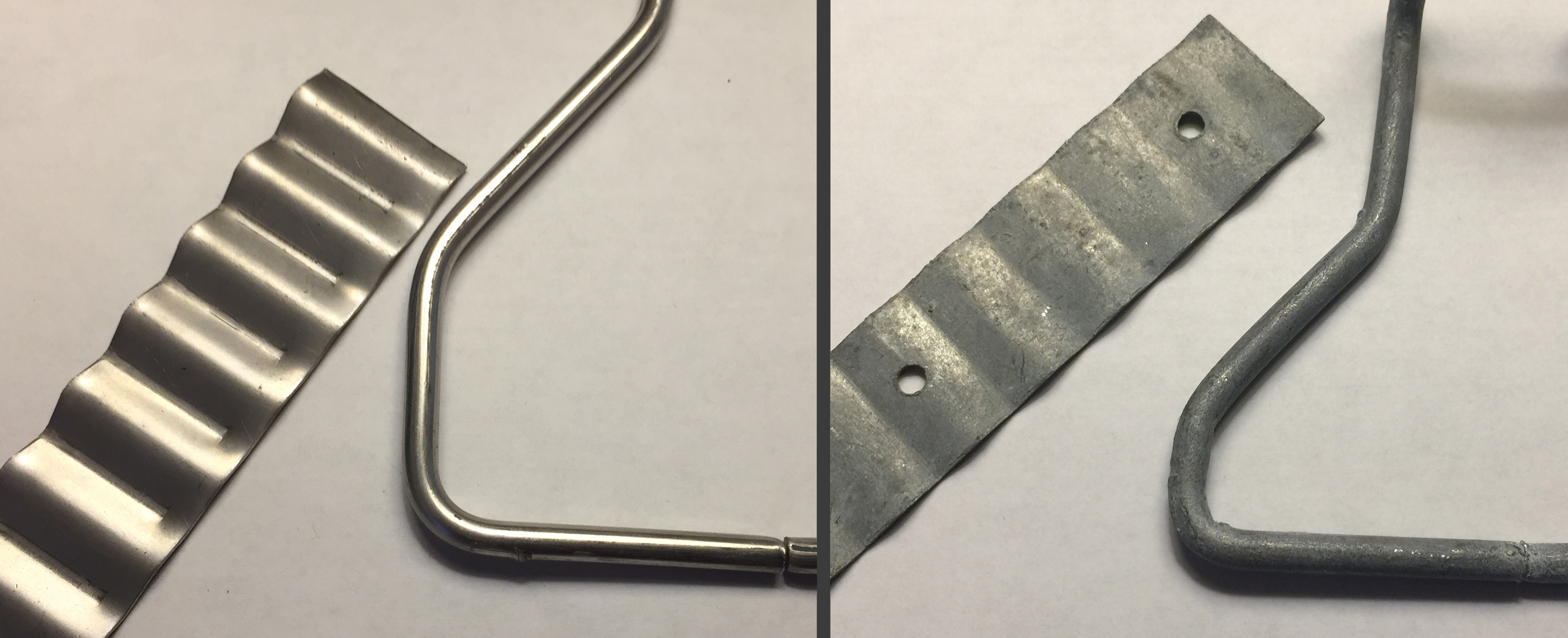

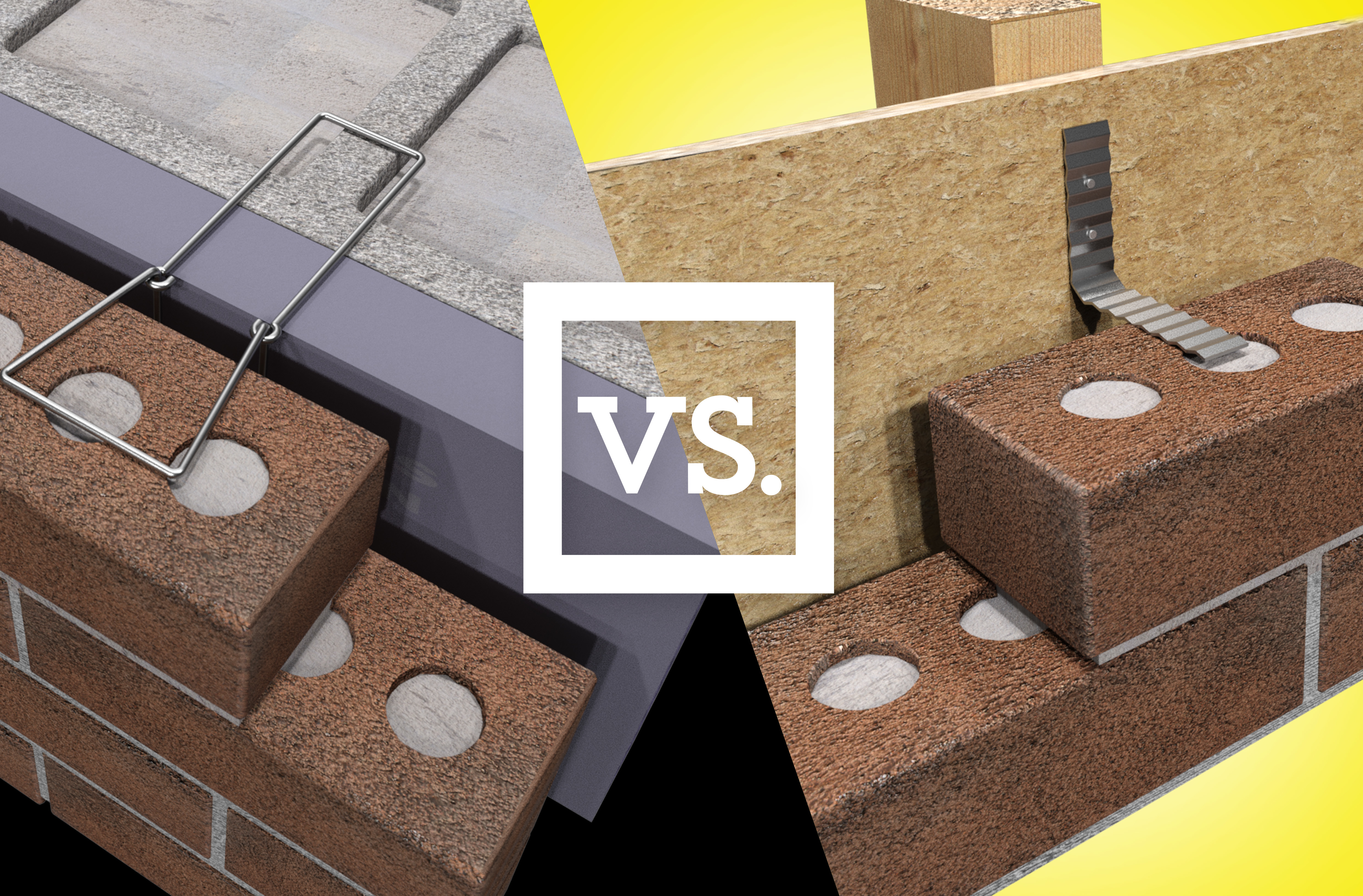

1. The Original Pos-I-Tie® is a two-piece system consisting of a Zamak zinc alloy barrel attached to the backup with a hot-dip galvanized wire tie installed in the mortar joint of the veneer. The wire tie loop allows for vertical adjustment of 1 ¼” above or below the plane of the barrel screw for placement in the mortar joint.

To install the Pos-I-Tie, a 2-piece adjustable veneer anchor, the barrel screw goes through the exterior sheathing insulation and attaches to the backup. The insulation hole is sealed with a factory-assembled EPDM washer. The veneer anchor is attached to the barrel screw for placement in the veneer.

The Original Pos-I-Tie® consists of one barrel screw and one anchor tie. The screw is part of the system and no inferior screws can be substituted. Barrel screws are installed after the sheathing is installed. This allows for use of full 4’ x 8’ sheets of insulation. The barrel screw pulls the sheathing tight against the backup preventing any moisture from reaching the backup through the layers of sheathing eliminating any need for a washer at the waterproofing level. The exterior hole is sealed by a factory-installed EPDM washer under the head of the barrel screw.

Barrels are measured from the base of the barrel to the center of the head flange. There are 9 standard barrel lengths: 5/8”, 1”, 1 ½”, 2”, 2 ½”, 3”, 3 ½”, 4”, 4 ½”. Custom lengths are available with our 1” factory installed extension units.

There are three types of screws:

Self-Drilling Steel Stud Screws are for 14 ga - 18 ga metal studs. There is no need to pre-drill holes, the barrel screw is self-drilling, self-tapping. 12/24” threads provide excellent holding capacity. Install a Check Adapter TOol and a 1500 rpm minimum drill.

CMU/Concrete/Wood/ICF Screws require a 3/16” diameter hole drilled to a minimum depth of 2” into the backup. For concrete over 5,000 psi, pre-drill a 7/32” hole. Wood backups do not require pre-drilling.

Structural Steel Screws. Structural Steel ½” and under typically do not have to be pre-drilled. Install with the Chuck Adapter Tool, thicker steel may require a pilot hole.

2. The ThermalClip® Pos-I-Tie® provides a thermal break between the veneer and the backup. Install the Original Pos-I-Tie and the ThermalClip Pos-I-Tie snaps onto the Pos-I-Tie in the airspace. The ThermalClip Pos-I-Tie uses a Pintle Wire Tie instead of the Triangle Tie. To install, first install the Original Pos-I-Tie, then insert the ThermalClip tab into the Pos-I-Tie and fold over. Listen for the two sides to “snap” into place and insert the Pintle Wire Tire.

3. The Pos-I-Tie® KeyBolt Stone Anchoring System, both the KeyBolt barrel and anchor are 304 stainless steel. It installs with a standard 5/16” chuck tool. The Double-Nut system allows for the transfer of larger loads than pintle type stone anchors. The Pos-I-Tie KeyBolt Stone Anchoring System allows for a ½” lateral adjustment. At the maximum extension, a 1-¾” minimum airspace is required.

To install, insert the barrel into the drill and screw through the insulation, continue drilling until the barrel makes contact with the backup wall. Tighten the back but so the washer dimples into the insulation. Insert the stone anchor and lower into the stone kerf. Make sure the anchor can’t slip out of the lower hole. Finally, tighten the outer nut.

The Thermal-Grip® washer is required for foil-faced insulation and also allows the Pos-I-Tie to be both a Veneer Anchor and a CI washer. Thermal-Grip® Continuous Insulation (CI) Washers (#610) are 2” diameters plastic washers used for attaching continuous rigid insulation (ci). Prongs enable pre-spotting into insulation (for fast on-the-wall faster assembly).